Magnetic Separators

Magnetic Separators Magnetic Separators are industrial solutions used to detect, extract, and separate ferrous contaminants from bulk materials, liquids, and product streams. They help protect equipment, improve product purity, and ensure smooth production across various industries. At Tesseract Systems, magnetic separators are engineered for high magnetic strength, reliable separation efficiency, and long service life in demanding industrial environments. Purpose & Working Principle Magnetic separators generate a controlled magnetic field that attracts iron-based particles as material flows through or over the system. The captured ferrous contaminants are safely removed, allowing clean material to continue through the process without interruption. Types of Magnetic Separators Drum Type Magnetic Separator Designed for continuous and automatic separation of ferrous materials from bulk products in recycling, mining, foundry, and manufacturing applications. Rotating magnetic drum for efficient separation Suitable for dry and wet processing conditions Consistent performance with minimal manual handling Belt Type Magnetic Separator Used for inline removal of tramp iron from conveyor-fed material streams, ensuring smooth and uninterrupted material flow. High-intensity magnets mounted over or within conveyors Effective removal of metal fragments and scrap Easy installation and low maintenance Key Advantages Protects machinery from metal damage Improves product quality and purity Reduces downtime and maintenance costs Reliable operation in harsh environments Applications Manufacturing and machining industries Bulk material processing Recycling and scrap handling Food, pharmaceutical, and chemical plants Mining, cement, and power industries Why Choose Tesseract Systems Every magnetic separator from Tesseract Systems is custom-engineered to match application requirements, ensuring dependable performance, seamless system integration, and long-term operational efficiency. ENQUIRY NOW →

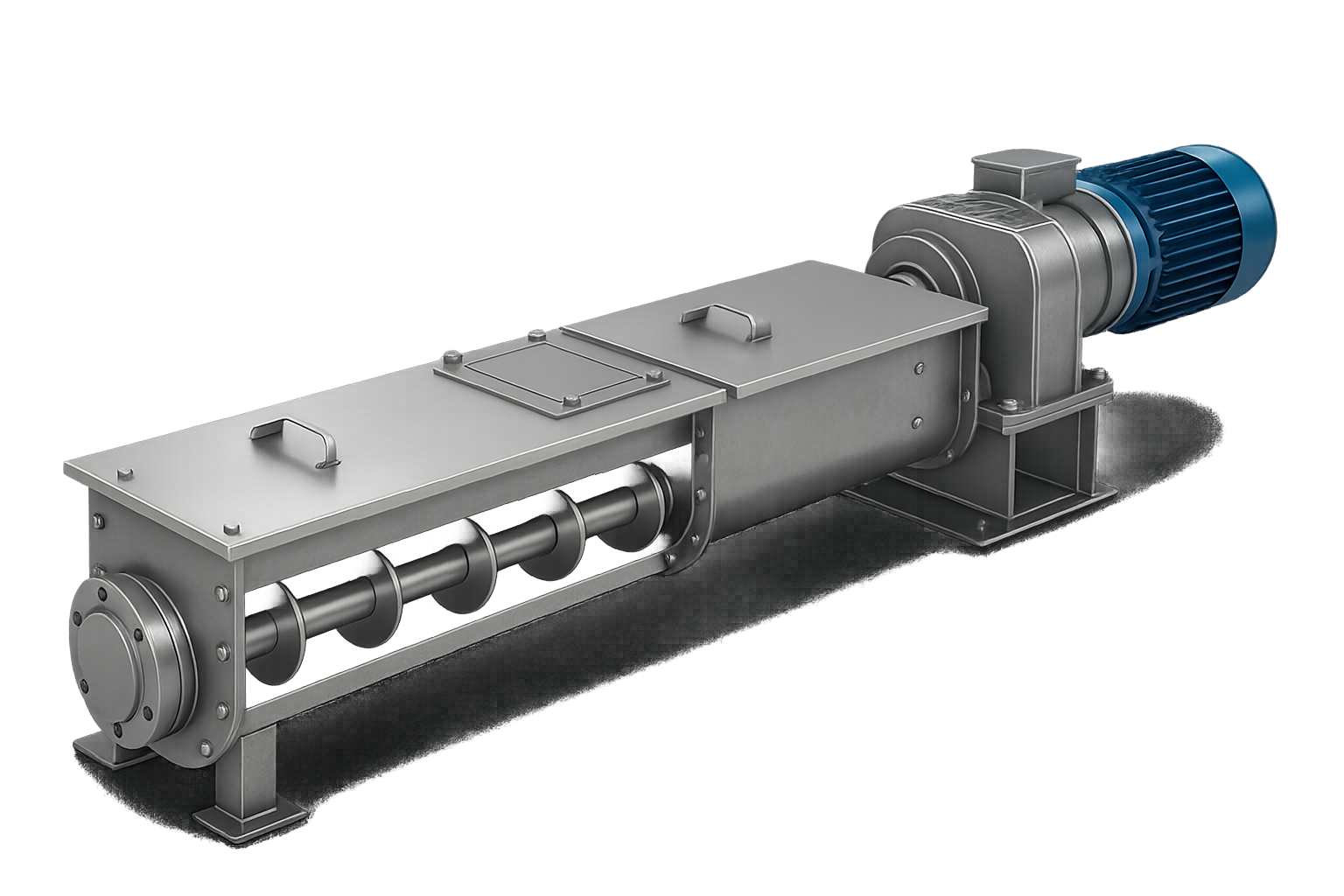

Drag Chain Conveyor

Drag Chain Conveyor A Drag Chain Conveyor is a rugged and efficient system used to move bulk materials through an enclosed trough using chain-driven flights. It’s ideal for abrasive, hot, or heavy-duty materials where belt conveyors may not be suitable. Structure & Drive The conveyor includes a continuous chain assembly fitted with scraper flights that drag material along the bottom of a sealed trough. A motor and gearbox drive ensure smooth, controlled movement with minimal dust generation and high mechanical strength. Key Features Handles abrasive, hot, or coarse materials effectively Fully enclosed design prevents dust and spillage Heavy-duty construction for long life High capacity and energy-efficient operation Low maintenance and quiet performance Typical Applications Used in cement, biomass, steel, foundry, and power industries for conveying ash, clinker, pellets, or coal safely and reliably. Tesseract Systems Expertise At Tesseract Systems, we engineer Drag Chain Conveyors built for performance, durability, and heavy-duty material handling. Our conveyors are designed to operate smoothly under demanding industrial conditions, ensuring maximum reliability and long-term efficiency. ENQUIRY NOW →

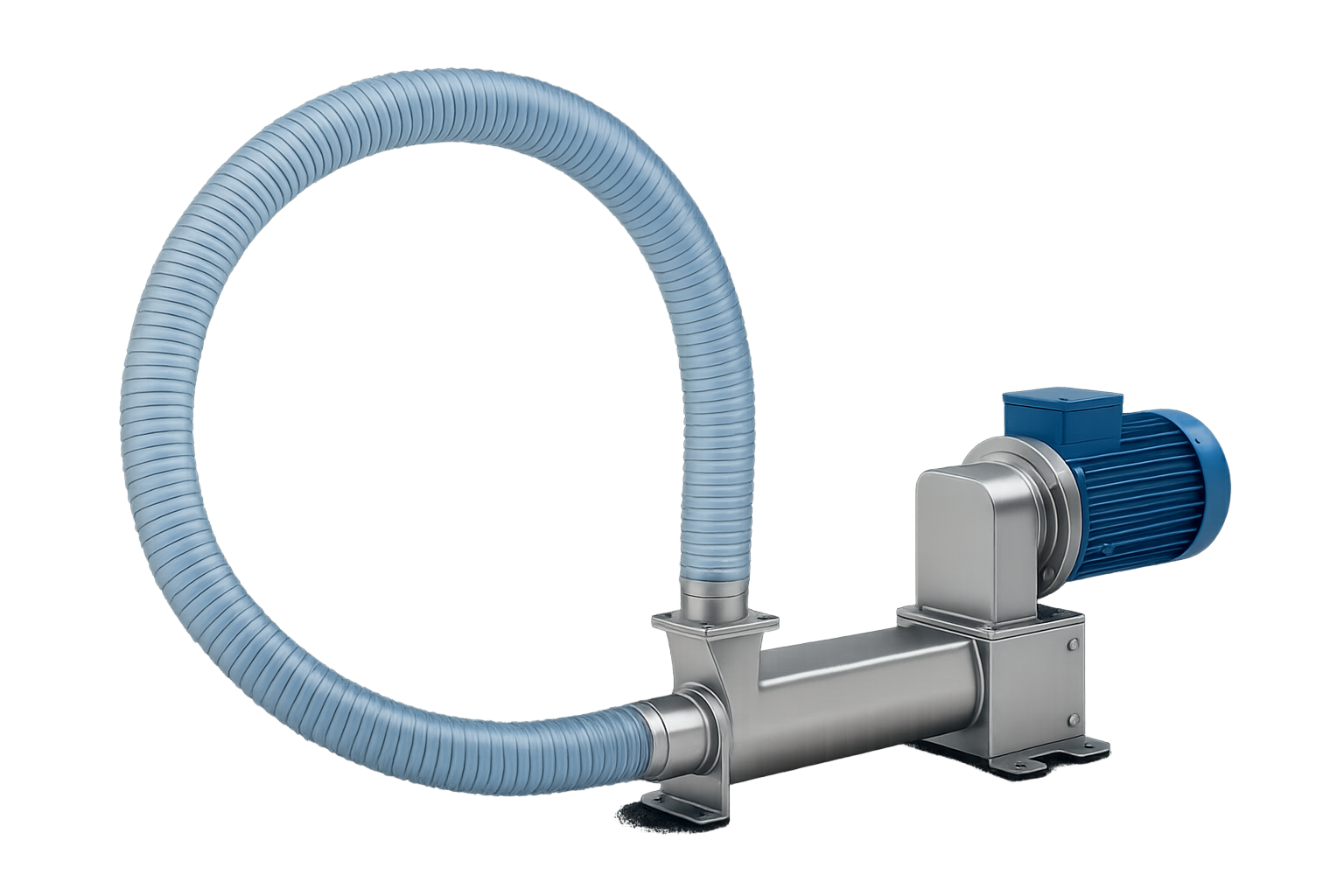

Flexible Hose Conveyor

Flexible Hose Conveyor A Flexible Hose Conveyor is an adaptable material handling system that uses a spiral-driven flexible hose to convey powders, granules, and other flowable materials through complex paths. It is ideal for plants where fixed conveyors are impractical or space is limited. Structure & Drive The system comprises a flexible hose or tube with an internal spiral or auger that moves materials through it. A motor and drive assembly powers the spiral, enabling easy transport around corners, elevations, or tight spaces with minimal residue or blockage. Key Features Highly flexible and space-saving design Gentle, enclosed material transfer Easy to clean and reconfigure Suitable for powders, granules, and small parts Portable and low maintenance Typical Applications Commonly used in food, pharmaceutical, plastic, and chemical industries for conveying powders, coffee, grains, or pellets safely and efficiently. Tesseract Systems Expertise At Tesseract Systems, we design Flexible Hose Conveyors that provide exceptional versatility, cleanliness, and efficiency. Our systems are ideal for complex layouts, offering a cost-effective and low-maintenance solution for transferring delicate or fine materials. ENQUIRY NOW →

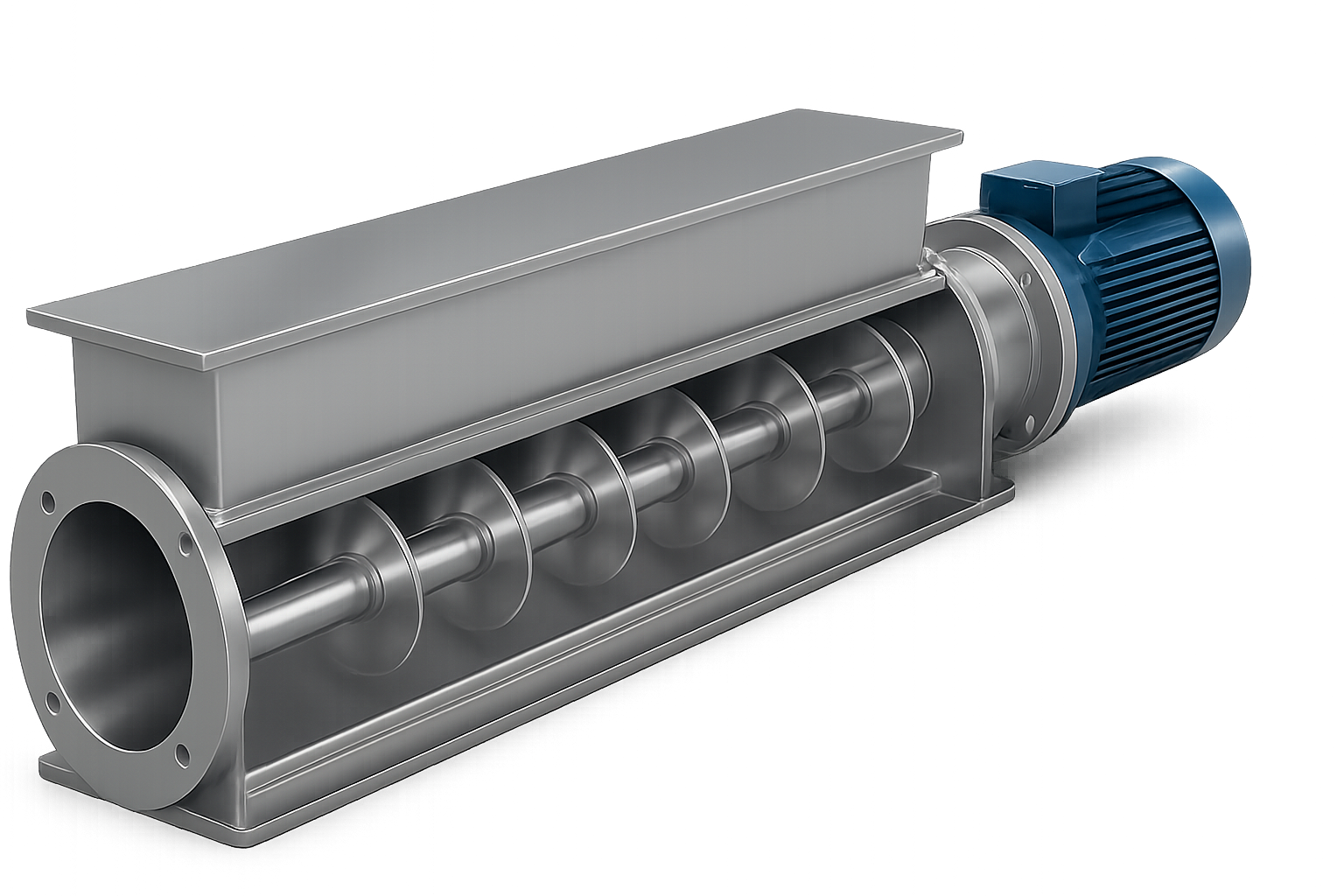

U-Trough Conveyor

U-Trough Conveyor A U-Trough Conveyor is an efficient material handling system used for transporting dry bulk materials in a U-shaped trough. It combines simplicity and durability, providing reliable conveying for medium to heavy-duty applications. Structure & Drive This conveyor features a U-shaped trough with a rotating screw or drag chain driven by a motorized gearbox assembly. The design minimizes spillage and allows easy material flow, while optional covers ensure dust-free operation. Key Features Strong, enclosed design for safe material handling Handles powders, granules, and semi-solids efficiently Customizable length, diameter, and material Easy to clean and maintain Suitable for inclined or horizontal transport Typical Applications Used in cement, food, fertilizer, chemical, and grain industries for conveying bulk materials like ash, flour, or feedstock. Tesseract Systems Expertise At Tesseract Systems, our U-Trough Conveyors are designed for long service life, superior performance, and operational safety. We offer customizable solutions to handle a wide range of materials while maintaining consistency, reliability, and efficiency. ENQUIRY NOW →

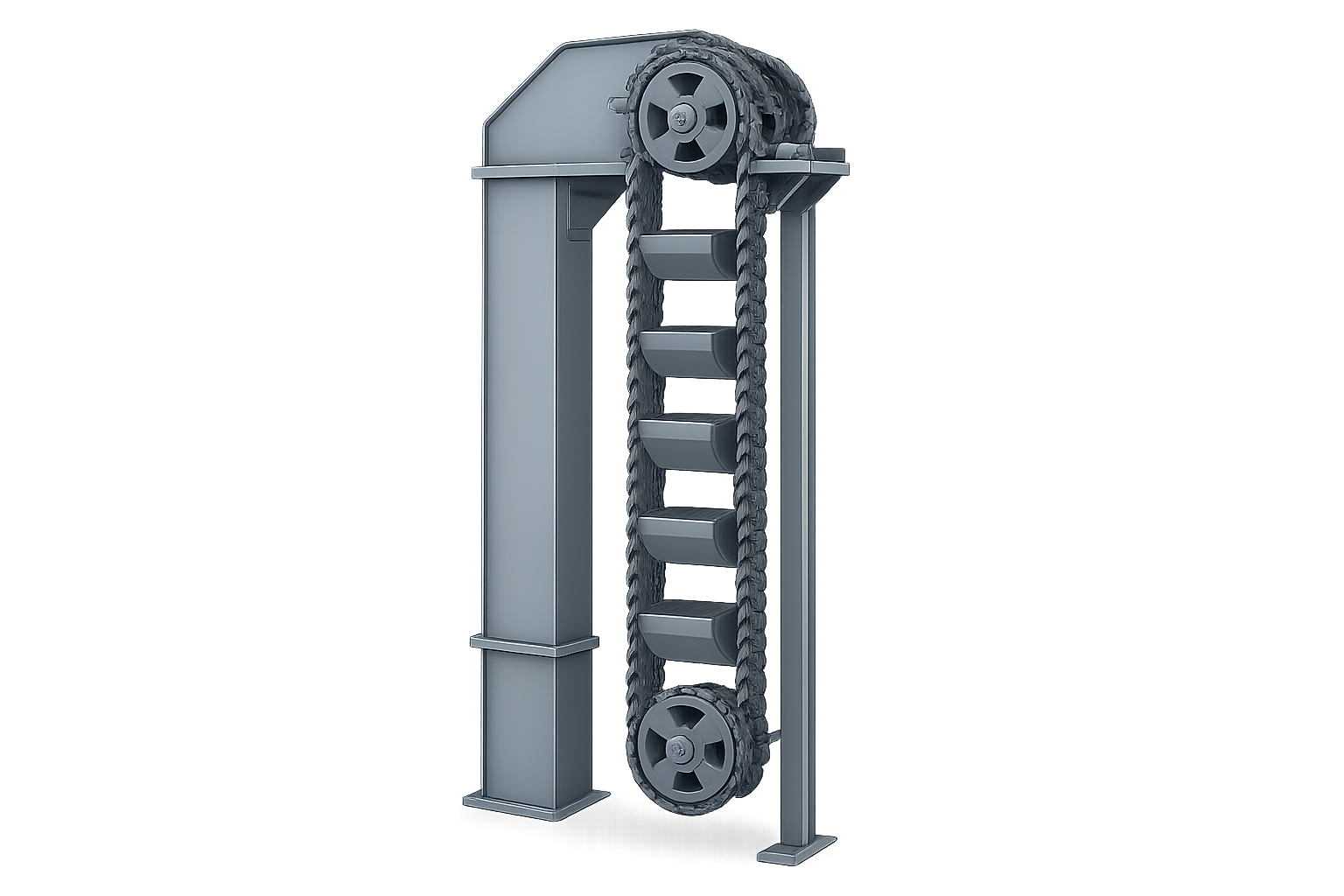

Bucket Conveyor

Bucket Conveyor A Bucket Conveyor is designed to vertically or inclinedly transport bulk materials using attached buckets mounted on a chain or belt. It provides gentle, efficient, and continuous handling of materials without spillage, making it perfect for fragile or granular products. Structure & Drive The conveyor consists of a series of buckets attached to a chain or belt assembly, driven by a motorized sprocket or pulley system. The buckets scoop up material from the inlet point and discharge it at the outlet, maintaining a steady vertical or inclined flow. Key Features Ideal for vertical or steep incline conveying Gentle handling of bulk and fragile materials Available in continuous or centrifugal discharge types Durable and easy to maintain Custom bucket sizes and materials Typical Applications Used in food, agricultural, chemical, and packaging industries for conveying grains, seeds, powders, or granules between process levels. Tesseract Systems Expertise At Tesseract Systems, we manufacture Bucket Conveyors that ensure smooth, spill-free, and gentle transfer of materials. Our conveyors are designed for efficiency and reliability, tailored to match your process requirements for vertical or inclined feeding applications. ENQUIRY NOW →

Vibratory Feeder

Vibratory Feeder A Vibratory Feeder uses controlled vibration to feed and move materials along a trough in a precise and measured manner. It’s widely used for feeding small components or bulk materials where gentle handling and accuracy are essential. Structure & Drive The system includes a vibrating tray or bowl mounted on springs and driven by an electromagnetic or motorized vibrator unit. The vibration causes materials to move steadily forward while maintaining an even flow rate. Key Features Accurate and consistent feeding control Gentle handling of fragile or delicate items Low noise and maintenance-free operation Customizable tray size and vibration frequency Suitable for continuous or batch feeding Typical Applications Commonly used in food, pharmaceuticals, packaging, electronics, and assembly systems for feeding tablets, fasteners, or other small components. Tesseract Systems Expertise At Tesseract Systems, our Vibratory Feeders are engineered for precision and durability. We customize vibration strength, tray design, and feed rate to ensure reliable material handling, improved process flow, and superior performance in demanding industrial conditions. ENQUIRY NOW →

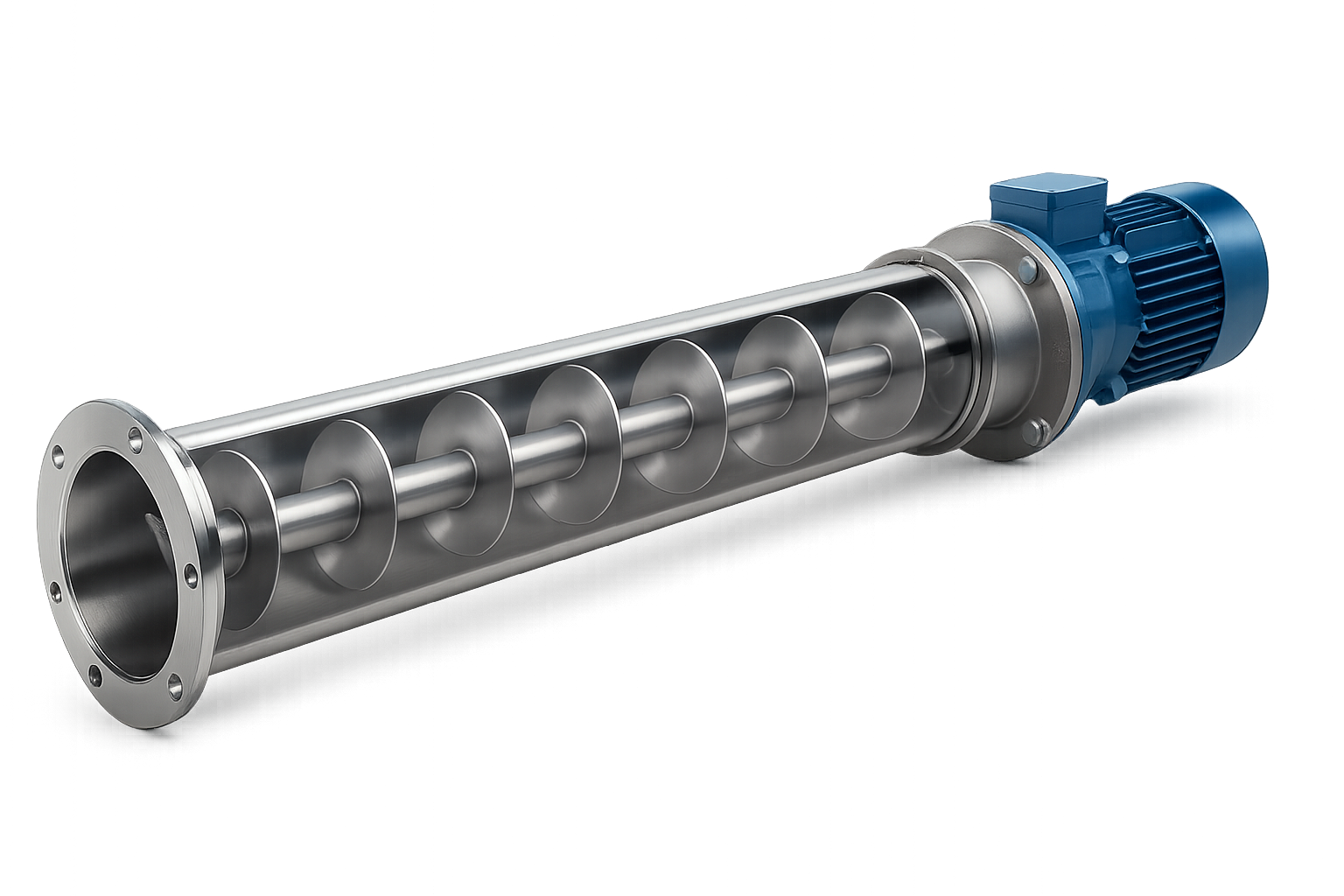

Screw Conveyor

A Screw Conveyor is an efficient mechanical system used to transport bulk materials horizontally or at an incline using a rotating helical screw blade inside a trough or tube. It provides uniform and controlled material flow, making it ideal for handling powders, granules, and semi-solid materials in enclosed conditions. Structure & Drive The system consists of a helical screw blade (flight) mounted on a rotating shaft enclosed in a tubular or U-shaped casing. The drive system includes an electric motor and gearbox that rotate the screw, propelling materials along the trough while preventing spillage and contamination. Key Features Enclosed design prevents dust and contamination Handles powders, grains, and semi-solid materials Customizable length, pitch, and diameter Simple, reliable, and low-maintenance operation Can be horizontal, inclined, or vertical Typical Applications Used in food, chemical, cement, fertilizer, and pharmaceutical industries for transporting dry bulk materials such as flour, sand, cement, or granules. Tesseract Systems Expertise At Tesseract Systems, we design and manufacture Screw Conveyors with precision-engineered components for maximum efficiency and durability. Our conveyors are tailored for your material type and process requirements, ensuring consistent feeding and smooth operation in every industrial environment. ENQUIRY NOW →

Curved Slat Conveyor

Curved Slat Conveyor A Curved Slat Conveyor is a specialized conveyor system designed to smoothly transport materials around curves or corners without product orientation loss. It uses a continuous chain-driven slat arrangement that follows a fixed curved path, ensuring consistent product flow in limited floor spaces. Ideal for heavy or irregularly shaped items, it provides smooth, stable, and efficient conveying through bends. Structure & Drive The conveyor is constructed with a sturdy steel frame supporting precision-engineered slats mounted on roller chains. The slats can be made from stainless steel, mild steel, or plastic depending on the application. The system is driven by a motorized chain drive that ensures reliable and synchronized movement even through tight curves, maintaining alignment and product stability throughout the conveying path. Key Features Designed for curved paths and space optimization Chain-driven for heavy-duty, continuous operation Durable slats suitable for various product types Low vibration and smooth product transfer Customizable curve angle, width, and slat material Typical Applications Widely used in automotive, packaging, bottling, assembly lines, and material handling systems where products must be conveyed around corners or integrated into U-shaped layouts without manual repositioning. Tesseract Systems Expertise At Tesseract Systems, we design and manufacture Curved Slat Conveyors tailored to specific industrial layouts and handling needs. Our conveyors combine robust engineering with smooth operational performance, ensuring efficient material flow and long-term reliability. Whether for heavy components or delicate products, Tesseract Systems delivers precision-built curved conveyor solutions that enhance space utilization and production efficiency. ENQUIRY NOW →

Wire Mesh Conveyor

Wire Mesh Conveyor A Wire Mesh Conveyor is a versatile and durable conveying system designed for continuous operation in high-temperature or harsh environments. It features a woven wire mesh belt that provides excellent ventilation, drainage, and strength, making it suitable for handling hot, oily, or wet materials. This conveyor ensures consistent performance and reliable product transfer in challenging industrial conditions. Structure & Drive The conveyor consists of a stainless steel or mild steel frame fitted with a wire mesh belt driven by sprockets or chain assemblies. The open mesh design allows air or liquid to pass freely through the belt, making it ideal for drying, cooling, heating, or washing applications. The drive system uses a motor and gearbox for smooth, uniform movement and adjustable speed control. Key Features Open mesh design for ventilation, drainage, and easy cleaning Withstands high temperatures and corrosive environments Durable construction with long belt life Customizable width, mesh type, and material Low maintenance and reliable performance Typical Applications Commonly used in food processing, heat treatment, baking, washing, drying, painting, and metalworking industries for conveying materials under high heat or wet conditions. Tesseract Systems Expertise At Tesseract Systems, we manufacture custom Wire Mesh Conveyors engineered for durability, performance, and temperature resistance. Our conveyors are built using premium-grade wire mesh belts and precision drive components to ensure smooth operation and long service life. Whether for cooling, heating, or drying applications, Tesseract Systems delivers efficient conveying solutions that maintain product quality and production efficiency. ENQUIRY NOW →

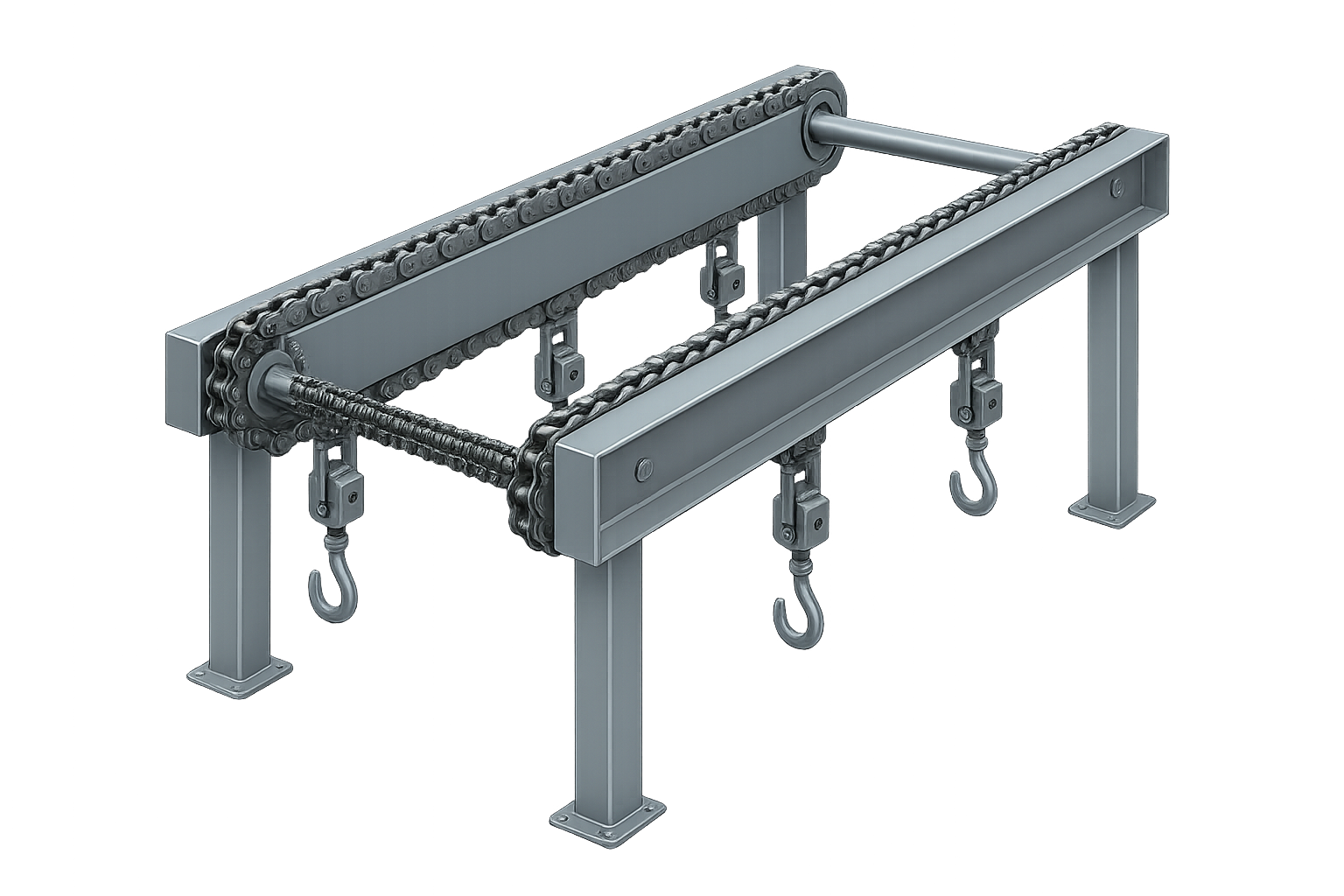

Pallet chain conveyor

Pallet Chain Conveyor A Pallet Chain Conveyor is a heavy-duty conveying system specifically designed for transporting pallets, skids, and large containers. It provides smooth, stable, and reliable movement of heavy loads across production, assembly, or warehouse environments. Built for strength and durability, this conveyor ensures consistent operation under demanding industrial conditions. Structure & Drive The conveyor consists of a robust steel framework equipped with two or more parallel chain-driven strands that support and move pallets directly. The system is powered by a motor and gearbox drive that transmits motion through sprockets and drive shafts. Designed for heavy loads, it allows bi-directional movement and can be integrated with transfer units or turntables for flexible layout configurations. Key Features Engineered for handling heavy pallets and industrial loads Durable chain-driven system ensures reliable performance Customizable chain pitch, speed, and load capacity Low maintenance and long service life Compatible with automation and transfer systems Typical Applications Widely used in automotive, logistics, warehousing, assembly lines, and manufacturing industries for moving pallets, crates, or large containers between processes or workstations. Tesseract Systems Expertise At Tesseract Systems, we specialize in designing and manufacturing Pallet Chain Conveyors that deliver strength, precision, and long-lasting performance. Our conveyors are built with high-quality components and robust engineering to handle continuous heavy-duty operations. With custom configurations and advanced control options, Tesseract Systems provides reliable pallet conveying solutions that optimize efficiency and streamline industrial workflows. ENQUIRY NOW →