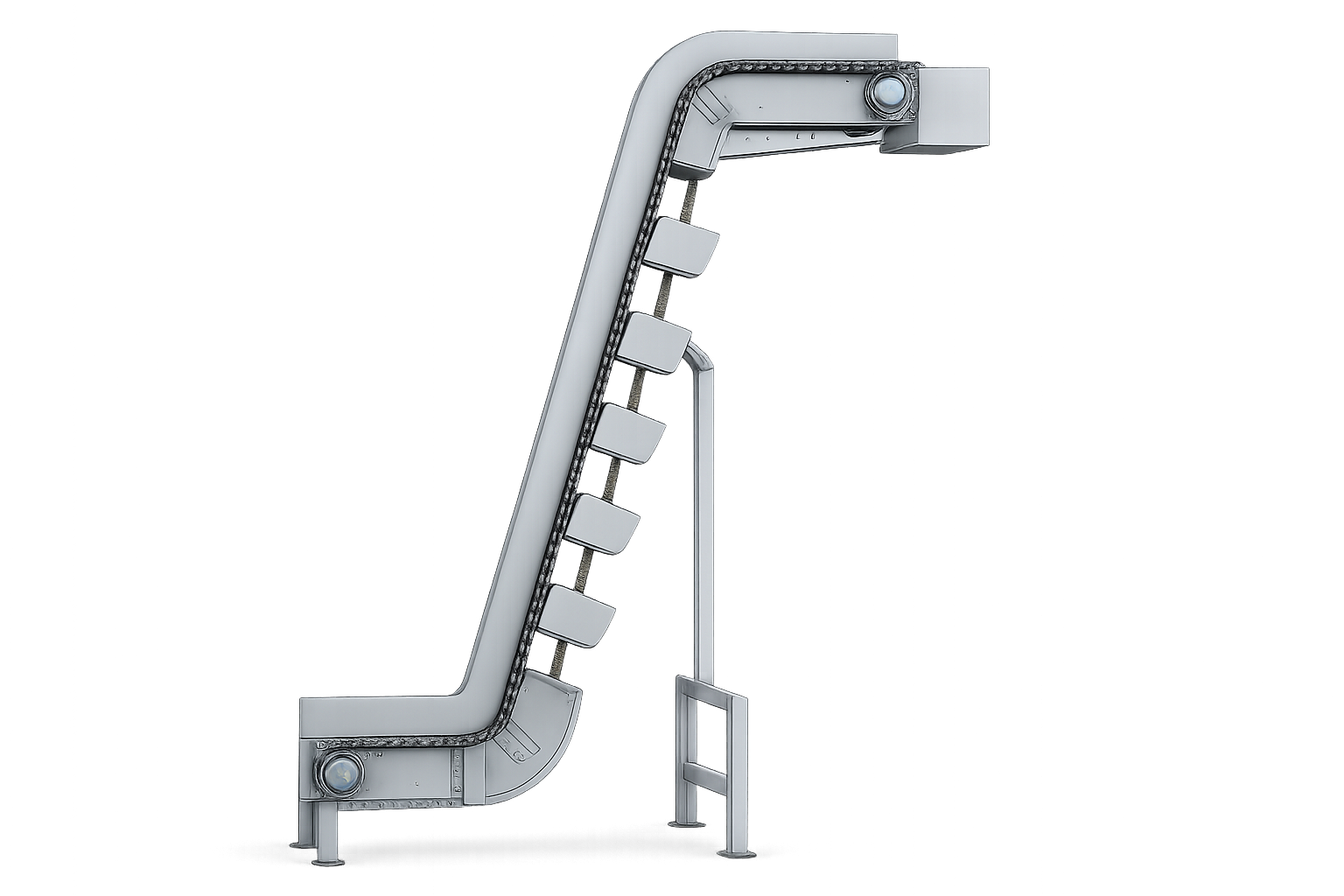

Bucket Chain Conveyor

Bucket Chain Conveyor A Bucket Chain Conveyor is a robust and reliable material handling system designed for the vertical and inclined transport of bulk materials. It consists of a series of buckets attached to a continuous chain, allowing smooth lifting and controlled discharge of materials such as grains, powders, aggregates, or granules. This conveyor is ideal for applications that require gentle handling with minimal spillage. Structure & Drive The conveyor features a heavy-duty chain assembly with securely mounted buckets, driven by a motor and gearbox through sprockets located at the head and tail ends. The design can be configured for horizontal-vertical-horizontal (Z-type) or straight-line conveying depending on layout needs. Constructed with durable materials, it ensures reliable operation even under high load or temperature conditions. Key Features Efficient vertical and inclined conveying for bulk materials Durable chain and bucket design for long service life Minimal spillage and dust generation Customizable bucket size, chain pitch, and speed Low maintenance and continuous operation Typical Applications Widely used in food processing, agriculture, cement, mining, chemical, and manufacturing industries for lifting granular or powdered materials safely and efficiently. Tesseract Systems Expertise At Tesseract Systems, we design and manufacture custom Bucket Chain Conveyors engineered for reliability and durability. Our conveyors are built with precision-driven chains, wear-resistant buckets, and robust frameworks to ensure smooth material flow and maximum uptime. With advanced design and superior craftsmanship, Tesseract Systems provides efficient vertical conveying solutions that enhance productivity and reduce material handling time. ENQUIRY NOW →

Z Type Chain Conveyor

Z-Type Chain Conveyor A Z-Type Chain Conveyor is an efficient vertical conveying system designed to move materials between different height levels in a compact layout. Its unique Z-shaped design allows products to be transferred smoothly in upward or downward directions while maintaining continuous flow. This conveyor is ideal for industries where space optimization and reliable elevation handling are essential. Structure & Drive The conveyor is built with a sturdy steel or stainless-steel frame and features a chain-driven system with attached slats, buckets, or fixtures depending on the product type. The Z-shaped path consists of horizontal, inclined, and vertical sections, powered by a motor and gearbox drive that ensures smooth, controlled, and efficient movement across elevation levels. Key Features Space-saving Z-shaped design for vertical and inclined conveying Heavy-duty chain drive ensures stability and durability Customizable for height, speed, and material type Low maintenance and long service life Suitable for continuous lifting of bulk or unit materials Typical Applications Commonly used in automotive, food processing, packaging, and manufacturing industries for transferring products between floors, machines, or process levels efficiently within limited space. Tesseract Systems Expertise At Tesseract Systems, we specialize in designing and manufacturing custom Z-Type Chain Conveyors that combine precision, durability, and performance. Our conveyors are engineered with high-quality materials and advanced chain mechanisms to ensure reliable elevation handling and smooth operation. With space-efficient designs and superior engineering, Tesseract Systems delivers conveying solutions that maximize productivity and optimize plant layout. ENQUIRY NOW →

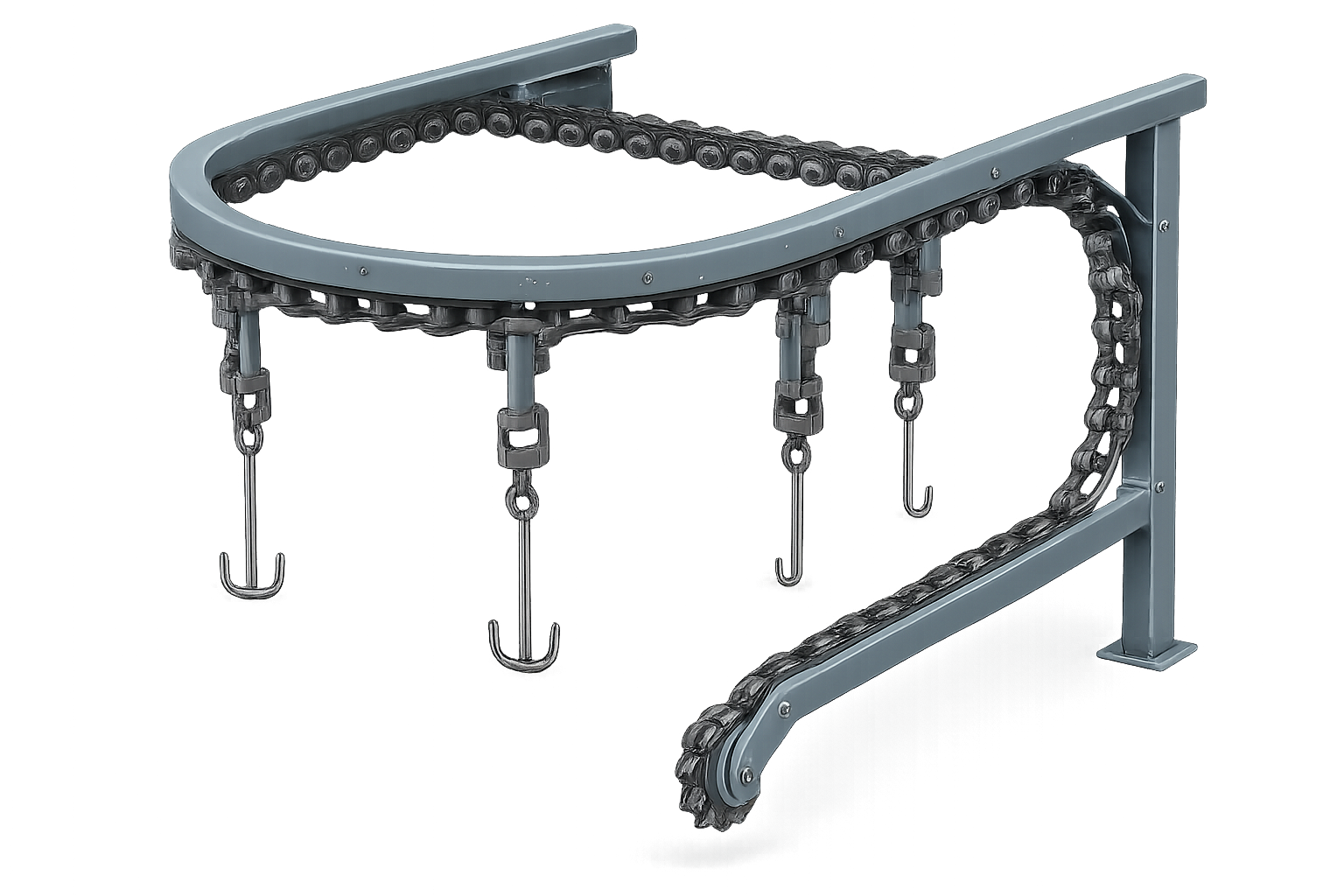

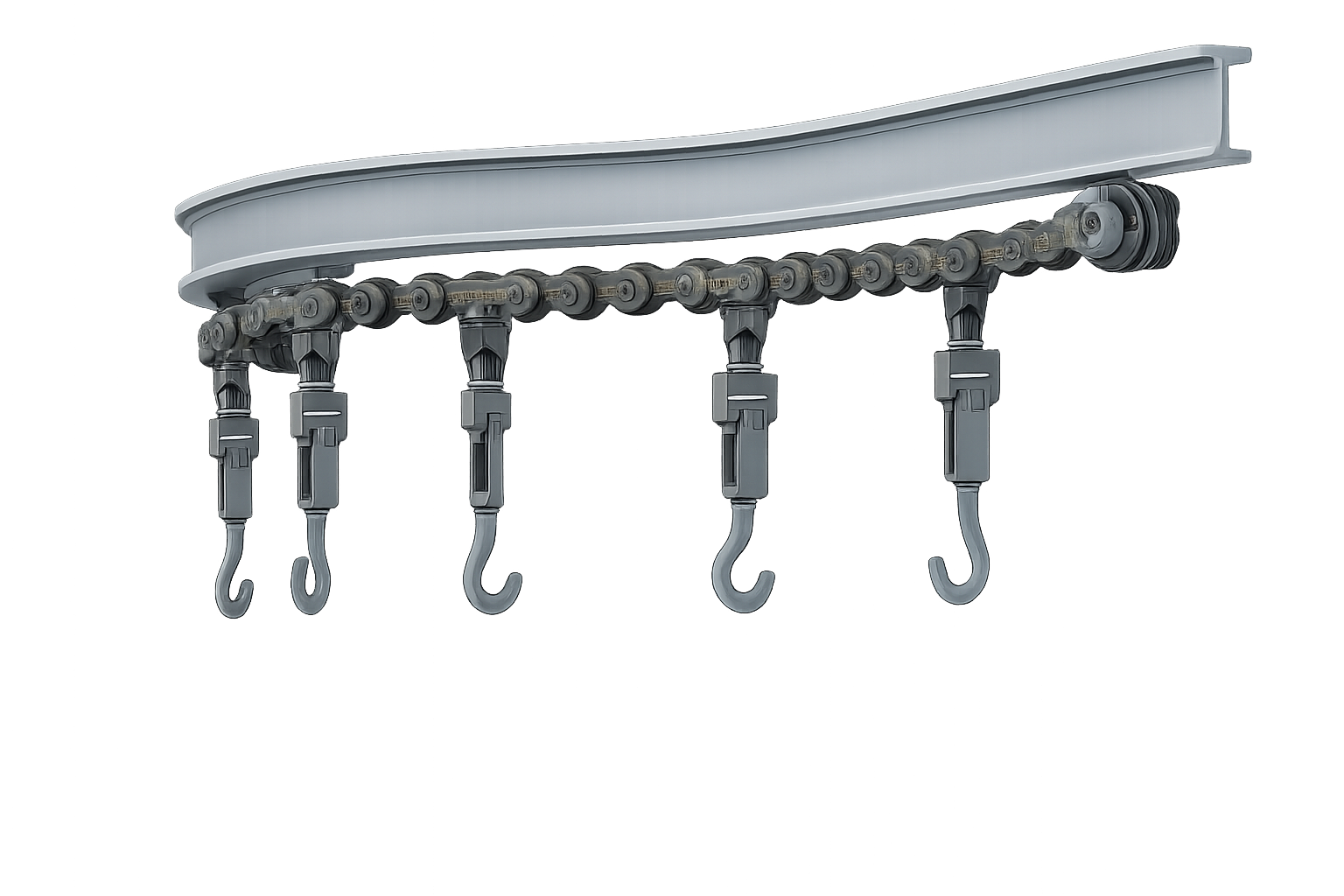

Overhead Chain Conveyor

Slat Chain Conveyor A Slat Chain Conveyor is a reliable and versatile conveying system designed to handle a wide variety of materials, from heavy components to delicate products. It features interlinked slats or plates attached to a chain drive, providing a continuous and stable conveying surface. This design ensures smooth, controlled movement, even for products that are unsuitable for roller or belt conveyors. Structure & Drive The conveyor consists of a series of slats or plates mounted on a chain-driven mechanism, supported by a sturdy steel or stainless-steel frame. The slats are available in various materials — such as steel, plastic, or stainless steel — depending on the application. A motor and gearbox drive unit powers the chain, enabling precise and continuous product flow through straight, curved, or inclined paths. Key Features Strong and stable conveying surface for heavy or irregular products Customizable slat width, pitch, and material Capable of handling high temperatures and harsh conditions Low noise operation with smooth and efficient performance Easy to clean and maintain, ideal for hygienic applications Typical Applications Widely used in automotive, packaging, bottling, food processing, and assembly industries for transporting containers, parts, or hot products that require a solid and durable conveying surface. Tesseract Systems Expertise At Tesseract Systems, we specialize in the design and manufacturing of custom Slat Chain Conveyors that deliver strength, durability, and precision. Our conveyors are built with high-quality materials, advanced chain drives, and modular configurations to ensure long service life and seamless integration with your production line. Tesseract Systems provides reliable conveying solutions that improve efficiency and performance across diverse industrial environments. ENQUIRY NOW →

Slat Chain Conveyor

Slat Chain Conveyor A Slat Chain Conveyor is a reliable and versatile conveying system designed to handle a wide variety of materials, from heavy components to delicate products. It features interlinked slats or plates attached to a chain drive, providing a continuous and stable conveying surface. This design ensures smooth, controlled movement, even for products that are unsuitable for roller or belt conveyors. Structure & Drive The conveyor consists of a series of slats or plates mounted on a chain-driven mechanism, supported by a sturdy steel or stainless-steel frame. The slats are available in various materials — such as steel, plastic, or stainless steel — depending on the application. A motor and gearbox drive unit powers the chain, enabling precise and continuous product flow through straight, curved, or inclined paths. Key Features Strong and stable conveying surface for heavy or irregular products Customizable slat width, pitch, and material Capable of handling high temperatures and harsh conditions Low noise operation with smooth and efficient performance Easy to clean and maintain, ideal for hygienic applications Typical Applications Widely used in automotive, packaging, bottling, food processing, and assembly industries for transporting containers, parts, or hot products that require a solid and durable conveying surface. Tesseract Systems Expertise At Tesseract Systems, we specialize in the design and manufacturing of custom Slat Chain Conveyors that deliver strength, durability, and precision. Our conveyors are built with high-quality materials, advanced chain drives, and modular configurations to ensure long service life and seamless integration with your production line. Tesseract Systems provides reliable conveying solutions that improve efficiency and performance across diverse industrial environments. ENQUIRY NOW →

Standard chain conveyor

Standard Chain Conveyor A Standard Chain Conveyor is a robust and durable material handling system designed for moving heavy loads, pallets, containers, and industrial components. It uses a continuous chain drive mechanism to ensure smooth and consistent transport of materials in demanding environments. Ideal for heavy-duty operations, this conveyor provides strength, reliability, and long-term performance. Structure & Drive The conveyor consists of a sturdy steel frame equipped with precision-engineered chain-driven rollers or slats that provide reliable traction and load support. The drive system is powered by a motor and gearbox assembly that ensures uniform speed and efficient movement. Depending on the layout, it can be configured for single, double, or multi-strand chains to handle different load capacities. Key Features Heavy-duty design for tough industrial applications Chain-driven system ensures smooth and synchronized movement Capable of handling pallets, drums, and bulky loads Customizable width, chain type, and layout configuration Durable construction with minimal maintenance Typical Applications Widely used in automotive, manufacturing, assembly lines, paint shops, and warehousing systems for transporting heavy products, components, or pallets efficiently between workstations. Tesseract Systems Expertise At Tesseract Systems, we specialize in designing and manufacturing Standard Chain Conveyors tailored to heavy-duty industrial needs. Our conveyors are built using high-quality chains, precision drives, and robust frameworks to deliver maximum durability, reliability, and performance. With our customized engineering solutions, we ensure seamless integration and long-lasting operation for your material handling system. ENQUIRY NOW →

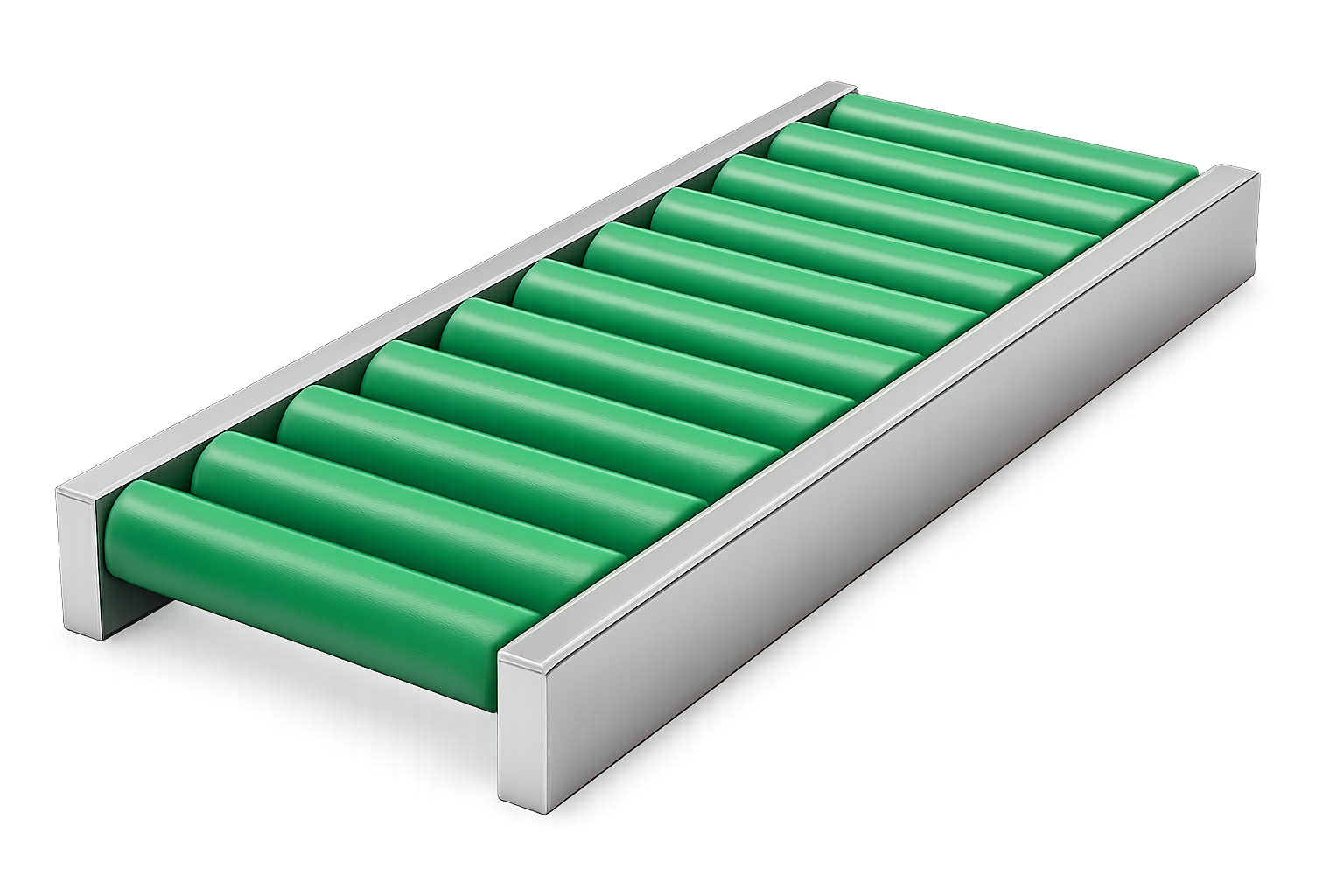

PU Roller Conveyor

PU Roller Conveyor A PU Roller Conveyor is designed for hygienic and smooth handling of sensitive products. Its rollers are coated with polyurethane (PU) for a quiet, non-marking, and wear-resistant surface. It is an ideal choice for industries that demand clean, gentle, and efficient material transfer such as food, pharmaceuticals, and electronics. Structure & Drive The PU Roller Conveyor includes precision-engineered PU-coated rollers mounted on a stainless steel or aluminum frame. Depending on process requirements, it can be configured as a gravity or motorized conveyor. The PU coating ensures low noise, superior grip, and easy cleaning. Key Features Hygienic, food-grade PU coating Low noise and vibration-free performance Resistant to wear, corrosion, and chemicals Ideal for cleanroom and sterile applications Easy to clean and maintain Typical Applications Widely used in food processing, pharmaceuticals, packaging lines, and cleanroom environments where hygiene and gentle material handling are critical. Tesseract Systems Expertise At Tesseract Systems, we specialize in building custom PU Roller Conveyors that meet industry-specific hygiene and performance standards. Our conveyors ensure safe, smooth, and quiet transport of delicate materials while maintaining maximum operational efficiency. ENQUIRY NOW →

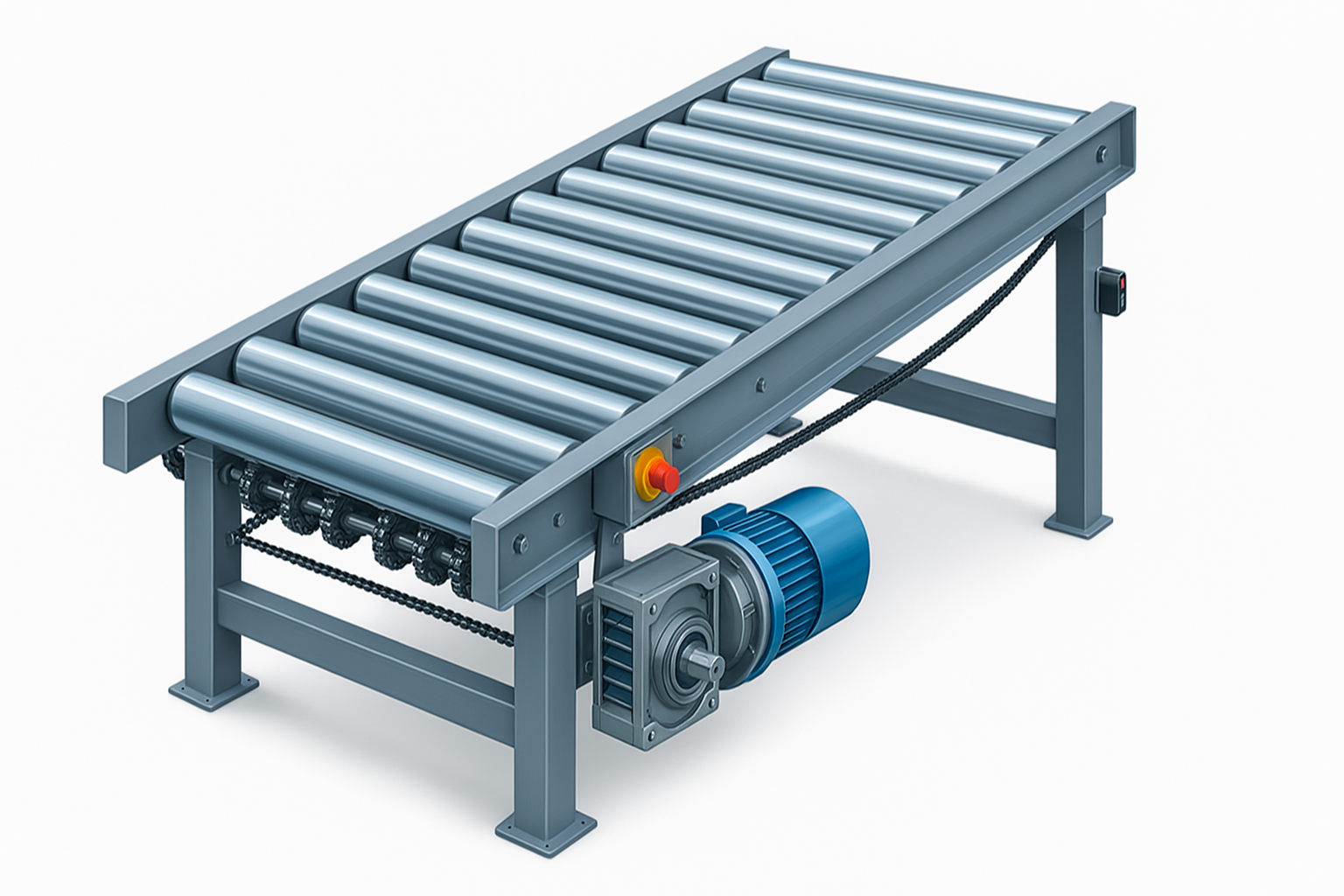

Power Roller Conveyor

Power Roller Conveyor A Power Roller Conveyor is a motor-driven conveyor system designed for continuous and controlled material movement. It ensures smooth and efficient product flow, making it ideal for assembly lines, distribution centers, and other automated systems where precision and speed are essential. Structure & Drive This conveyor uses motorized rollers or chain drives mounted on a sturdy frame to transport materials automatically. The system allows speed regulation, directional control, and easy integration with automation or sensor-based operations for improved productivity. Key Features Motorized drive for efficient, continuous transport Adjustable speed and direction control Smooth, vibration-free product handling Low noise and minimal maintenance Compatible with automated systems Typical Applications Used in assembly lines, packaging plants, logistics hubs, and warehouses for handling boxes, crates, and medium to heavy loads. Tesseract Systems Expertise At Tesseract Systems, we build high-performance Power Roller Conveyors using durable materials and energy-efficient drives. Each conveyor is engineered for reliability, automation compatibility, and precision handling to meet the needs of modern manufacturing and logistics industries. ENQUIRY NOW →

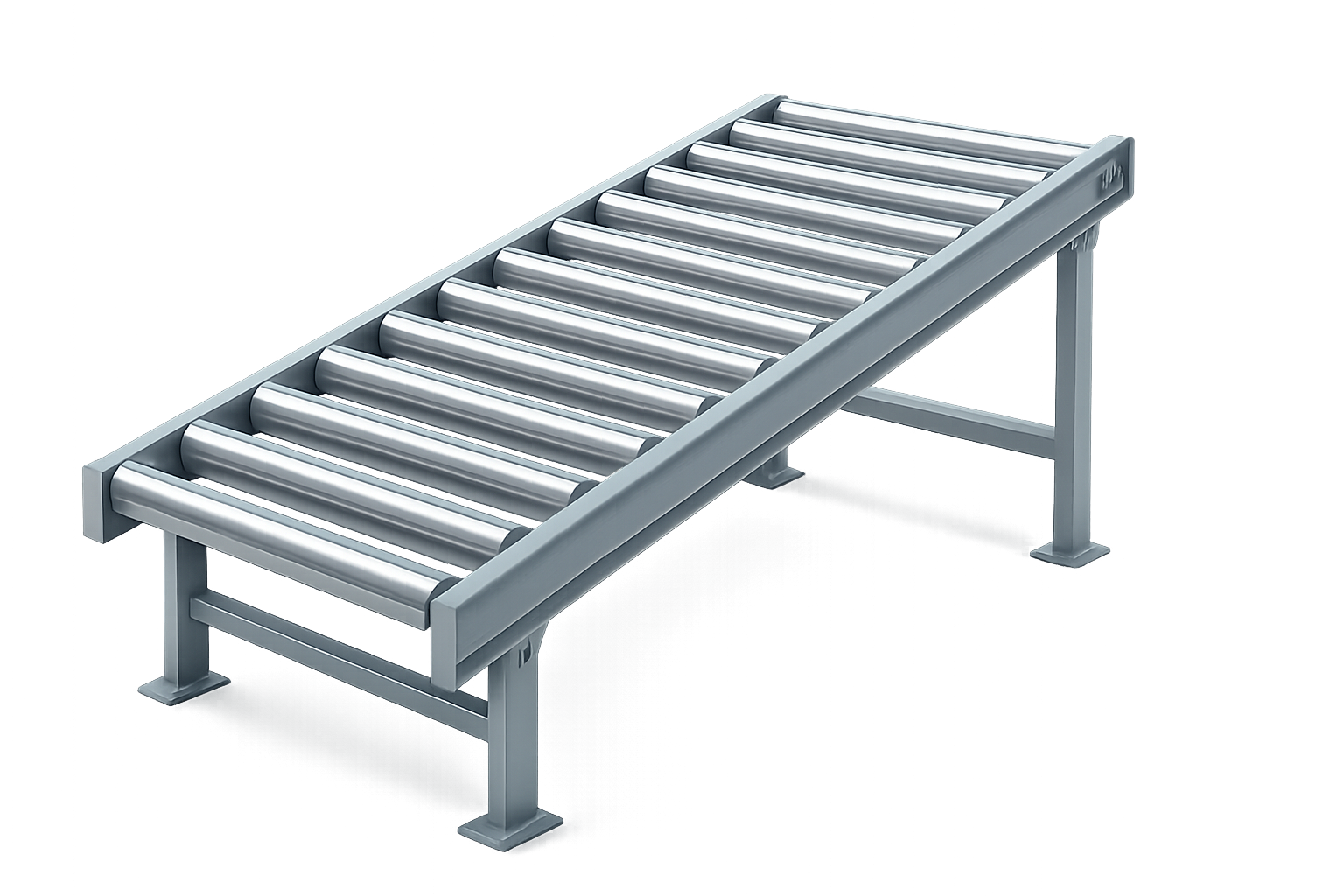

Gravity Roller Conveyor

Gravity Roller Conveyor A Gravity Roller Conveyor is one of the simplest and most efficient material handling systems, designed to move goods smoothly using the natural force of gravity. It operates without any motorized drive, offering a low-cost and low-maintenance conveying solution. Built with durable rollers and a sturdy frame, it ensures smooth and reliable performance for various industrial uses. Structure & Drive The conveyor consists of a robust framework fitted with free-rolling steel or PVC rollers that rotate as items pass over them. Since it operates purely on gravity, there is no need for power or drive components such as motors or gearboxes. This simple yet durable structure ensures minimal wear, long service life, and easy integration with existing systems. Key Features Energy-efficient and eco-friendly (no power required) Low installation and operating cost Easy to install, extend, or relocate Minimal maintenance and downtime Suitable for boxes, cartons, and light to medium loads Typical Applications Widely used in warehouses, packaging lines, dispatch areas, and manual loading zones where products are moved or accumulated by gravity. Tesseract Systems Expertise At Tesseract Systems, we specialize in designing and manufacturing customized Gravity Roller Conveyors that improve workflow efficiency. Our precision-engineered rollers and high-quality frames ensure safe, smooth, and durable material movement for industrial environments. ENQUIRY NOW →

Rubber Roller Conveyor

A Rubber Roller Conveyor is a durable and high-performance material handling system designed for superior grip, vibration damping, and impact resistance. The rollers are coated with rubber sleeves that provide excellent traction, making them ideal for handling heavy or irregularly shaped loads with stability and control. This conveyor type is widely used in automotive, packaging, and manufacturing industries for efficient and reliable material transport. Structure & Drive The Rubber Roller Conveyor features a heavy-duty steel frame fitted with rubber-coated rollers. It can be configured as a gravity-driven or power-driven system depending on application requirements. The rubber coating minimizes slippage, absorbs shock, and reduces noise, ensuring smooth and safe handling even in demanding industrial environments. Key Features High-grip rubber rollers for stable material movement Excellent shock and vibration absorption Low noise and smooth operation Heavy-duty construction for industrial use Available in gravity or powered configurations Typical Applications Commonly used in automotive assembly lines, packaging units, warehouses, and heavy material handling zones where load stability and durability are essential. Tesseract Systems Expertise At Tesseract Systems, we design and manufacture custom Rubber Roller Conveyors engineered for strength, performance, and long-term reliability. Our conveyors use premium rubber coatings and precision rollers to ensure consistent, safe, and efficient transport. Whether for heavy-duty manufacturing or automated packaging, Tesseract Systems delivers robust conveyor solutions that maximize productivity and operational efficiency. ENQUIRY NOW →

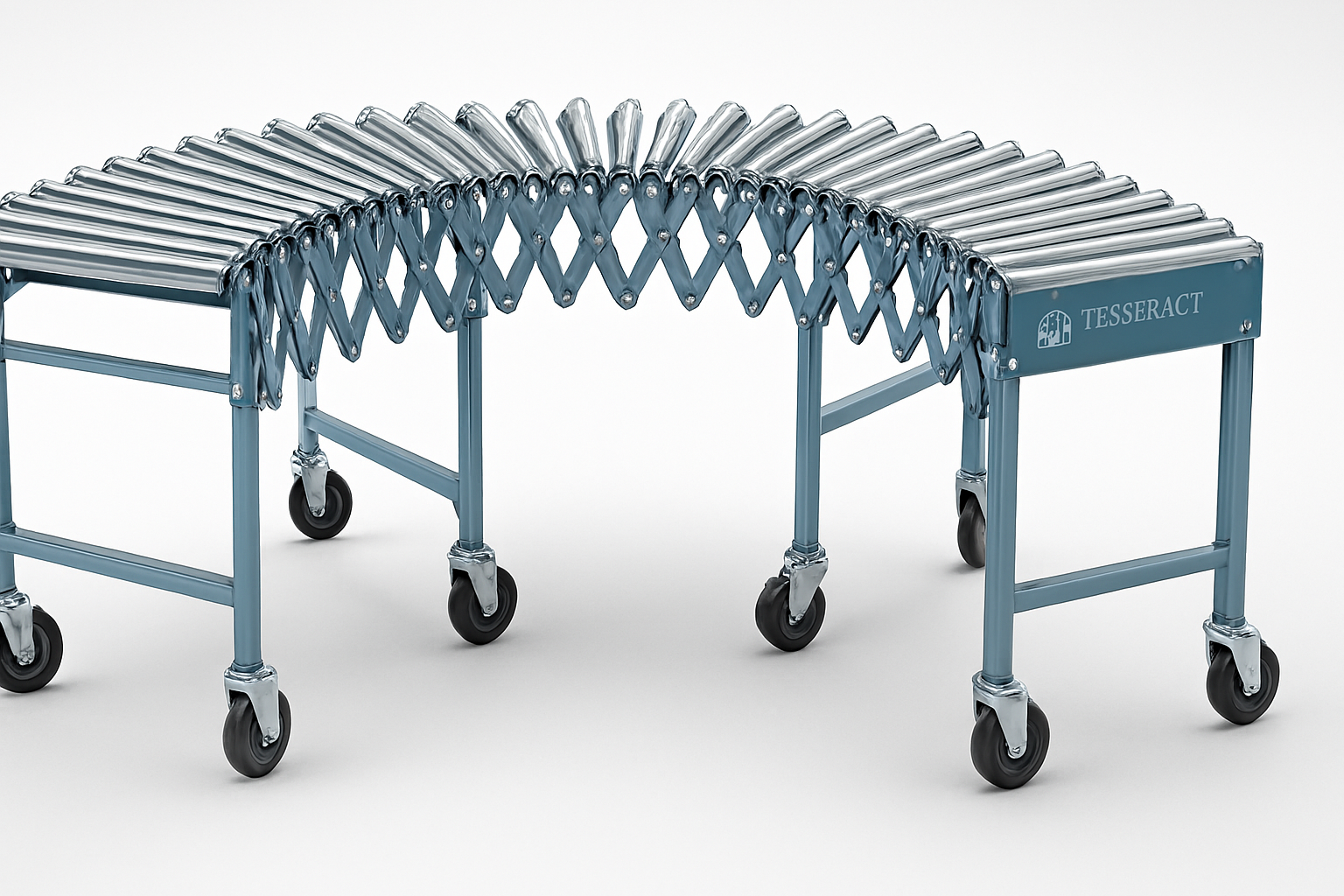

Flexible Roller Conveyor

A Flexible Roller Conveyor is a versatile and space-efficient material handling solution designed to expand, contract, and curve easily to suit dynamic work environments. Built with durable rollers mounted on a flexible, accordion-style frame, it allows quick layout changes and effortless movement of goods. This adaptability makes it ideal for loading, unloading, and packaging applications in busy warehouses or dispatch areas. Structure & Drive The Flexible Roller Conveyor features a lightweight yet robust expandable frame fitted with free-rolling steel or PVC rollers. It operates without a motor, relying on manual push or gravity for movement. Heavy-duty castor wheels with locking brakes ensure easy mobility and stability during operation, allowing the conveyor to bend and adjust to required positions. Key Features Flexible, extendable, and easy to reposition Compact storage and quick setup Smooth material flow and reduced manual effort Lockable castor wheels for stability Ideal for cartons, parcels, and totes Typical Applications Widely used in dispatch zones, truck loading/unloading, packaging stations, and temporary conveyor setups, Flexible Roller Conveyors are perfect for spaces where layout changes frequently or mobility is essential. Tesseract Systems Expertise At Tesseract Systems, we design and manufacture custom Flexible Roller Conveyors that combine durability, smooth performance, and mobility. Our conveyors are engineered with precision rollers, high-quality frames, and reliable locking mechanisms to handle demanding industrial operations. Whether for e-commerce, logistics, or packaging facilities, Tesseract Systems provides efficient and user-friendly conveyor solutions that save space and boost productivity. ENQUIRY NOW →