Feeding Conveyors

Feeding Conveyors are specialized conveyor systems designed to regulate and deliver materials smoothly and consistently into subsequent processing or packaging equipment. They act as the starting point of many production or assembly lines, ensuring a steady, controlled flow of materials without interruptions or overloading downstream machinery. Built for accuracy, reliability, and adaptability, Feeding Conveyors play a crucial role in maintaining efficiency and productivity across diverse industrial applications. These conveyors are widely used in **food processing, pharmaceuticals, packaging, agriculture, manufacturing, and recycling industries, where continuous and uniform material feeding is essential. Depending on the application, they can handle **granules, powders, bulk materials, or finished products, ensuring precise transfer rates that align with the production process. Feeding Conveyors can be integrated with hoppers, weighing systems, vibratory feeders, or automated machinery for synchronized operation. Types of Feeding Conveyors 1. Belt Feeding Conveyors – Provide smooth and consistent feeding for both light and heavy materials, ideal for general production use. 2. Screw or Auger Feeding Conveyors– Used for powders, granules, or semi-solid materials, ensuring precise and controlled feeding. 3. Vibratory Feeding Conveyors– Offer accurate feeding for delicate or small components without damage, common in food and electronics industries. 4. Chain Feeding Conveyors – Designed for heavy-duty materials or pallets, providing strong and stable feeding in industrial environments. 5. Z-Type Feeding Conveyors – Suitable for vertical or inclined feeding applications where elevation change is required. At **Tesseract Systems**, we specialize in **custom-engineered Feeding Conveyors** designed to match specific production requirements and material characteristics. Our conveyors are built using **high-quality materials, precision drives, and hygienic or heavy-duty designs**, depending on the application. We ensure smooth integration with existing equipment and automation systems to achieve consistent, efficient, and reliable feeding performance. By combining **engineering expertise, innovation, and attention to detail**, **Tesseract Systems** delivers Feeding Conveyors that enhance workflow, minimize manual handling, and optimize process continuity, ensuring seamless operation and improved productivity in every industrial setup. . ENQUIRY NOW →

Chain Conveyors

Chain Conveyors are heavy-duty material handling systems designed to transport large, bulky, or palletized loads with strength and reliability. Unlike belt or roller conveyors, these systems use a continuous chain loop—typically made of steel—that engages directly with the load or with specially designed fixtures. This makes them ideal for applications where durability, precision, and high load capacity are critical. Chain Conveyors are widely used in automotive, manufacturing, warehousing, foundries, and assembly lines, where they efficiently move items such as pallets, containers, machine parts, and heavy components. Their rugged construction allows them to perform in demanding environments involving **high temperatures, heavy loads, or oily and dirty conditions**. They can be configured for straight-line transport, accumulation, or integration with lifts and automated transfer systems. Types of Chain Conveyors 1. Single Strand Chain Conveyors – Used for light to medium loads where compact design and efficient movement are required. 2. Double or Triple Strand Chain Conveyors – Designed for handling pallets, drums, and heavy industrial loads that require balanced support. 3. Drag Chain Conveyors – Used to move bulk materials or powders inside enclosed housings, ideal for dust-free transport. 4.Overhead Chain Conveyors** – Suspend loads from a chain running overhead, maximizing floor space and enabling flexible movement through complex paths. 5. Slat Chain Conveyors – Use slats attached to chains for stable transport of unit loads, perfect for assembly lines or hot, sharp, or oily products. At Tesseract Systems, we specialize in designing and manufacturing **custom-engineered Chain Conveyors** built to meet the toughest industrial demands. Our systems are crafted from **high-strength steel, corrosion-resistant components, and precision-engineered drives** to ensure smooth operation, long life, and minimal maintenance. Each conveyor is tailored to the customer’s layout, load capacity, and process requirements for maximum performance. With expertise in **automation integration and advanced material handling solutions**, **Tesseract Systems** delivers Chain Conveyors that provide **durability, precision, and efficiency**, ensuring reliable movement of heavy materials and optimized workflow across industrial operations. ENQUIRY NOW →

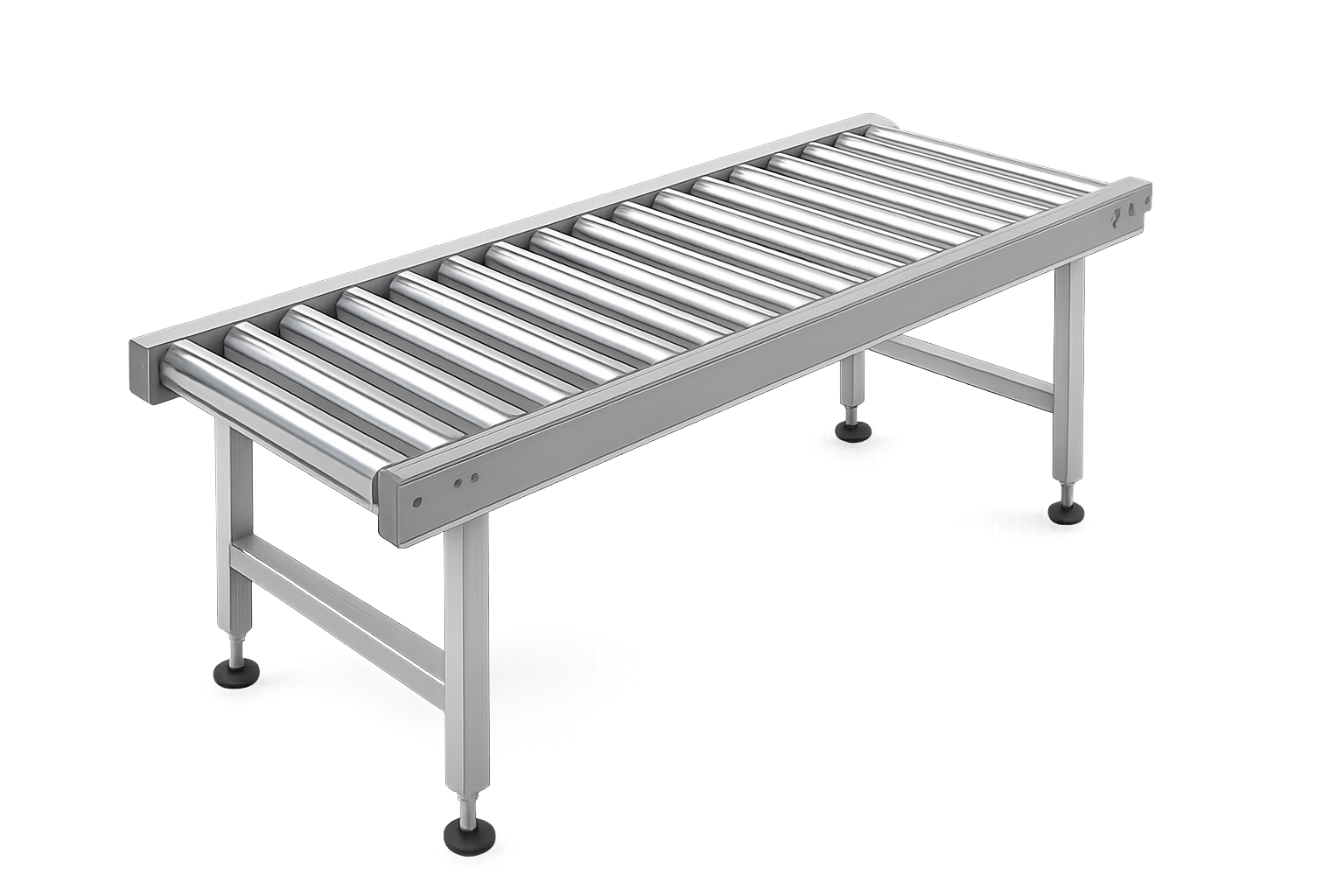

Roller Conveyors

Roller Conveyors are robust and efficient material handling systems designed to transport goods, packages, or components smoothly using a series of rollers mounted in a frame. They enable easy and reliable movement of items—either manually, by gravity, or through motorized power—depending on the application. With their simple yet durable design, Roller Conveyors are ideal for handling a wide range of products, from lightweight cartons to heavy pallets, across short or long distances. These conveyors are widely used in **warehousing, manufacturing, packaging, logistics, distribution centers, and assembly lines**, where they help streamline operations, reduce manual handling, and improve process efficiency. The roller-based structure allows for smooth transfer, accumulation, sorting, and assembly, making them suitable for both straight and curved conveyor paths. ### **Types of Roller Conveyors** 1. **Gravity Roller Conveyors** – Operate without power, using gravity or manual push to move goods; perfect for lightweight or free-rolling products. 2. **Powered Roller Conveyors** – Driven by motors or chains for continuous, controlled movement of heavy or high-volume materials. 3. **Chain-Driven Roller Conveyors** – Designed for heavy-duty applications, ensuring synchronized roller motion for large or palletized loads. 4. **Line Shaft Roller Conveyors** – Ideal for light to medium loads; use a rotating shaft to power multiple rollers efficiently. 5. **Accumulation Roller Conveyors** – Allow products to queue or buffer without contact or damage, commonly used in packaging and sorting lines. 6. **Curved Roller Conveyors** – Facilitate smooth directional changes within tight layouts, maintaining consistent product orientation. At **Tesseract Systems**, we specialize in **custom-engineered Roller Conveyors** tailored to the specific needs of each industry and operation. Our systems are built using **high-quality rollers, precision bearings, and durable frame constructions** that ensure long-lasting performance with minimal maintenance. We design conveyors that integrate seamlessly with automation systems, optimizing material flow and workspace efficiency. With a commitment to **engineering excellence, innovation, and reliability**, **Tesseract Systems** delivers Roller Conveyors that enhance workflow, boost productivity, and provide dependable material handling solutions for diverse industrial environments. ENQUIRY NOW →

Belt Conveyors

Belt Conveyors are among the most versatile and widely used material handling systems, designed to efficiently transport products or bulk materials in a smooth, continuous flow. They consist of a moving belt—made from durable materials such as rubber, PVC, or polyurethane—mounted over pulleys and driven by a motorized system. This simple yet effective mechanism enables the movement of items across varying distances, elevations, and layouts with precision and reliability. These conveyors are used across a broad range of industries, including **manufacturing, packaging, food processing, pharmaceuticals, logistics, and warehousing**, where they help streamline operations, reduce manual handling, and maintain consistent production flow. Belt Conveyors are known for their **versatility, low maintenance, and cost-effectiveness**, making them an essential component in modern material handling systems. Types of Belt Conveyors 1. Flat Belt Conveyors – Ideal for general material handling, assembly lines, inspection, and packaging processes. 2. Inclined Belt Conveyors – Designed to transport materials between different height levels while maintaining steady flow and control. 3. Z-Type Belt Conveyors – Used for vertical and inclined transfer of materials, saving floor space and improving workflow. 4. Curved Belt Conveyors– Enable smooth product flow around corners or within compact spaces without interrupting operations. 5. Modular Belt Conveyors– Built with interlocking belt segments for strength, flexibility, and easy maintenance—suitable for heavy or irregular products. 6. PU Belt Conveyors** – Made with food-grade polyurethane belts for hygienic and gentle handling in food, pharma, and cleanroom applications. At **Tesseract Systems**, we specialize in designing and manufacturing **custom-engineered Belt Conveyors** that meet the precise requirements of each application. Our conveyors are built using **robust materials, precision drive systems, and advanced engineering** to ensure durability, efficiency, and seamless integration with automated systems. By combining **innovation, quality craftsmanship, and industry expertise**, **Tesseract Systems** delivers a complete range of Belt Conveyors that enhance productivity, optimize space, and ensure reliable performance across diverse industrial environments. . ENQUIRY NOW →

PU Belt Conveyors

PU Belt Conveyors are specialized material handling systems designed for clean, hygienic, and gentle transportation of sensitive or delicate products. These conveyors feature food-grade polyurethane (PU) belts, which offer excellent resistance to oils, fats, chemicals, and microbial growth—making them ideal for environments where cleanliness and safety are paramount. They are widely used in food processing, pharmaceutical production, packaging, and cleanroom applications, where maintaining strict hygiene standards is essential. PU Belt Conveyors ensure smooth, non-contaminating product transfer while preventing damage to delicate items such as baked goods, packaged food, tablets, or medical components. The non-porous and easy-to-clean belt surface minimizes the risk of bacterial accumulation, supporting compliance with FDA and HACCP standards. At Tesseract Systems, we specialize in the design and manufacturing of precision-engineered PU Belt Conveyors that meet the highest safety and quality benchmarks. Our team customizes each system based on product type, production layout, and sanitation requirements. Every conveyor is constructed using stainless steel frames, sealed bearings, and modular hygienic designs for effortless cleaning and long-term durability. With a commitment to innovation and operational efficiency, Tesseract Systems delivers PU Belt Conveyors that ensure reliable performance, superior hygiene, and gentle handling, making them the trusted choice for industries where product safety and cleanliness define success. ENQUIRY NOW →

Modular Belt Conveyors

Modular Belt Conveyors are advanced conveying systems designed with interlocking plastic belt segments that provide exceptional durability, flexibility, and ease of maintenance. Unlike traditional flat belts, the modular design allows for smooth movement of products over straight, curved, or inclined paths, making them highly adaptable to complex layouts and demanding industrial environments. These conveyors are particularly suited for food processing, beverage production, packaging, pharmaceuticals, and general manufacturing applications, where hygiene, strength, and versatility are essential. The open-surface structure of modular belts ensures easy cleaning and drainage, while the robust interlocking links handle heavy-duty loads and irregularly shaped materials with precision and stability. Additionally, the design enables quick part replacement and minimal downtime, reducing maintenance costs and improving operational efficiency. At Tesseract Systems, we specialize in delivering custom-engineered Modular Belt Conveyors tailored to meet the specific needs of each industry and production process. Our expert engineering team designs conveyors using high-quality modular belt materials, corrosion-resistant components, and precision drive systems to ensure consistent performance and long service life. We focus on optimizing layout flexibility—whether the conveyor needs to curve, incline, or integrate into an automated line. Through innovation, engineering excellence, and customer-focused design, Tesseract Systems provides Modular Belt Conveyors that combine strength, hygiene, and reliability, ensuring smooth, efficient, and long-lasting material handling solutions for modern industrial operations. ENQUIRY NOW →

Curved Belt Conveyors

Curved Belt Conveyors are specialized conveying systems designed to smoothly transport materials around corners, curves, or tight spaces without interrupting product flow. Unlike straight conveyors, these systems maintain the orientation and alignment of products while changing direction—typically at angles of 45°, 90°, or 180°—allowing for seamless movement within complex or space-constrained production layouts. They are widely used in automated manufacturing lines, packaging units, distribution centers, airports, and logistics hubs, where efficient space utilization and uninterrupted transfer are critical. Curved Belt Conveyors ensure precise product tracking and gentle handling, making them ideal for items such as cartons, parcels, bottles, or food products that must remain stable during directional changes. At Tesseract Systems, we specialize in designing and manufacturing custom-engineered Curved Belt Conveyors that integrate perfectly into existing conveyor networks or new automated systems. Our engineering team focuses on achieving smooth belt tracking, minimal vibration, and accurate curve geometry to ensure consistent performance even under continuous, high-speed operation. Each unit is built with durable materials, precision bearings, and advanced drive mechanisms that guarantee long service life and low maintenance. By combining innovative design with practical functionality, Tesseract Systems delivers Curved Belt Conveyors that enhance workflow efficiency, optimize space utilization, and improve process continuity—bringing flexibility, control, and reliability to modern industrial operations. ENQUIRY NOW →

Inclined Belt Conveyors

Inclined Belt Conveyors are designed to efficiently transport materials between different height levels, making them an ideal solution for applications where elevation changes are a key part of the production or packaging process. These conveyors use a specially designed belt surface—often equipped with cleats or sidewalls—to prevent product slippage and ensure smooth, controlled movement even on steep inclines or declines. They are commonly used in manufacturing plants, warehouses, packaging units, and food processing industries, where materials need to be moved from ground level to hoppers, silos, mezzanines, or higher production lines. Inclined Belt Conveyors are highly versatile and can handle a wide variety of materials, from lightweight goods to bulk or heavy components, while maintaining continuous flow and gentle handling to prevent product damage. At Tesseract Systems, we specialize in engineering custom-built Inclined Belt Conveyors tailored to each customer’s layout, material characteristics, and operational requirements. Our design team ensures optimal angle selection, belt material choice, and drive configuration to achieve maximum efficiency, safety, and reliability. We incorporate high-quality materials, robust frames, and precision drive systems to deliver conveyors that perform consistently in demanding industrial environments. By focusing on innovation and ergonomic design, Tesseract Systems provides Inclined Belt Conveyors that not only improve productivity but also reduce manual handling and optimize floor space, ensuring smooth, automated movement of materials across different height levels in your production process. ENQUIRY NOW →

Flat Belt Conveyors

Flat Belt Conveyors are one of the most widely used and versatile material handling systems, designed to provide smooth, continuous, and efficient movement of goods across various stages of production. These conveyors consist of a flat, flexible belt stretched over pulleys that transport materials in a straight line—ideal for applications requiring accuracy, speed, and consistent performance. They are extensively used in assembly lines, inspection stations, packaging units, and general material transfer processes across industries such as manufacturing, logistics, electronics, and food processing. Flat Belt Conveyors are especially valued for their ability to handle both light and heavy loads with minimal noise, easy operation, and low maintenance. Their clean, flat surface ensures stable product transport, making them suitable for delicate items, cartons, and components that need precise handling. At Tesseract Systems, we specialize in designing and manufacturing custom-engineered Flat Belt Conveyors that perfectly align with each client’s workflow and production requirements. Our conveyors are built using high-quality belts and robust frame structures that ensure long-term reliability and smooth performance under continuous operation. Tesseract Systems integrates advanced drive systems, ergonomic design, and modular construction, allowing for easy installation, maintenance, and scalability. Whether you require a simple transport line or a fully automated material handling system, Tesseract Systems delivers Flat Belt Conveyors that combine innovation, durability, and efficiency—helping industries achieve seamless product flow and optimized productivity in every operation. ENQUIRY NOW →

Z-TYPE BELT CONVEYOR

Z-Type Belt Conveyors are specialized material handling systems designed to efficiently move products vertically or between different height levels with a continuous, smooth flow. Their unique “Z” configuration allows for both horizontal and inclined conveying within a compact footprint—making them ideal for facilities where floor space is limited but productivity cannot be compromised. These conveyors are widely used in industries such as food processing, pharmaceuticals, packaging, agriculture, and manufacturing, where gentle handling and precise transfer of materials are crucial. The upper and lower horizontal sections enable easy feeding and discharge of materials, while the inclined section ensures stable movement without spillage or product damage. At Tesseract Systems, we specialize in designing and manufacturing custom-built Z-Type Belt Conveyors tailored to specific operational needs. Our engineering team carefully analyzes product characteristics, load capacity, and layout constraints to create systems that deliver maximum efficiency and reliability. Using high-quality belts, corrosion-resistant frames, and precision-engineered drive mechanisms, Tesseract Systems ensures long-lasting performance even in demanding industrial environments. From compact modular designs to heavy-duty configurations, every Z-Type Conveyor from Tesseract Systems is optimized to enhance workflow, reduce manual handling, and streamline vertical transport in your production process—backed by our commitment to innovation, durability, and customer satisfaction. ENQUIRY NOW →